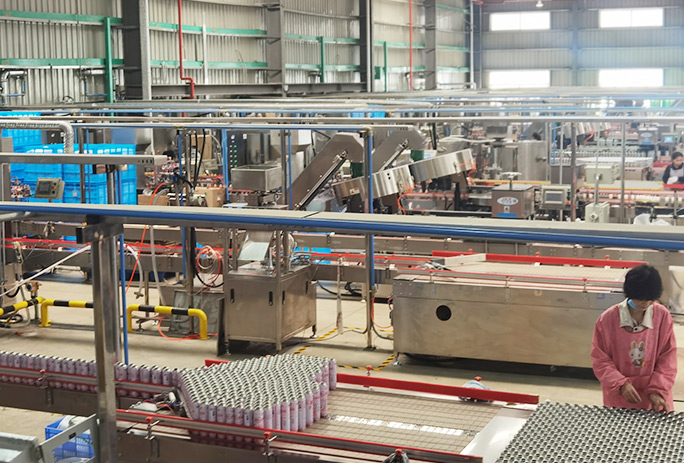

Aerosol Cans Production

As a manufacturer of all -industry chain production, we can give customers more timely support and more personalized solutions in the selection and purchasing of raw materials to seal, cans, and filling.

Cans making is the process of making metal sheets into cans of various shapes through a series of processing techniques. The can making process includes raw material preparation, molding, welding, surface treatment, testing and packaging.

+86 199 5793 1696

+86 199 5793 1696

ENG

ENG  English

English 中文简体

中文简体 عربى

عربى Español

Español русский

русский